Although it is more advanced in terms of product quality and production automation compared with inlay and brazing methods, there are still many shortcomings in the heat exchange efficiency and ash accumulation prevention of high frequency welded finned tubes due to factors such as difficulty in welding through the roots of high frequency welded finned tubes and creases in the roots.

The finned tube is a kind of heat exchange element. In order to improve the heat transfer efficiency, the surface of the heat exchanger tube is usually increased by adding fins to increase the external surface area (or internal surface area) of the heat exchanger tube, so as to achieve the purpose of improving the heat transfer efficiency, such a heat exchanger tube.

As a heat exchange element, the finned tube works under high temperature flue gas conditions for a long time, such as boiler heat exchanger with finned tube in a harsh environment, high temperature and pressure and in a corrosive atmosphere, which requires the finned tube should have high performance indicators.

1), Anti-corrosion

2), Anti-wear

3), lower contact resistance

4), Higher Stability

5), Anti-dust accumulation ability

Advantages of stainless steel laser welded spiral fins.

1. Using pulse laser welding technology, the welding around the piece is completed simultaneously, and the welding rate of the tube piece reaches 100%.

2. Laser welding is a metallurgical combination, the welding strength of the tube sheet can reach more than 600MPa.

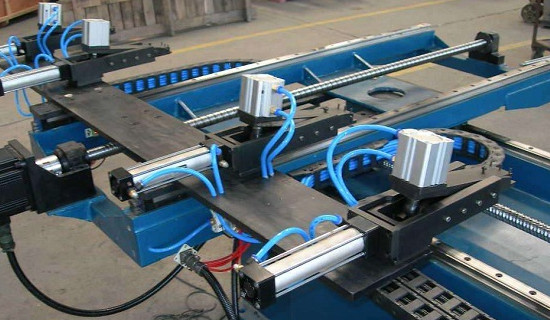

3. The laser welding machine adopts servo transmission system, the transmission accuracy can reach the Kumi level.

4. Laser welding fin tube piece distance can be ≤ 2.5mm, heat dissipation area than high frequency welding tube (piece distance ≥ 4.5mm) increased by nearly 50%, less consumables per unit area, can significantly reduce the heat exchanger volume.

Post time: Sep-30-2022