1. The entire machine frame is processed by Germany SHW pentahedron processing center at one time.

4. The shearing angle can be easily adjusted through programming to avoid the deformation of the workpiece caused by cutting.

5. The upper beam stroke length can be automatically adjusted to realize the fast and precise cutting of short and small workpiece in order to improve working efficiency.

6. The CNC system will automatically adjust the blades gap according to the different sheet thickness and material to improve cutting quality.

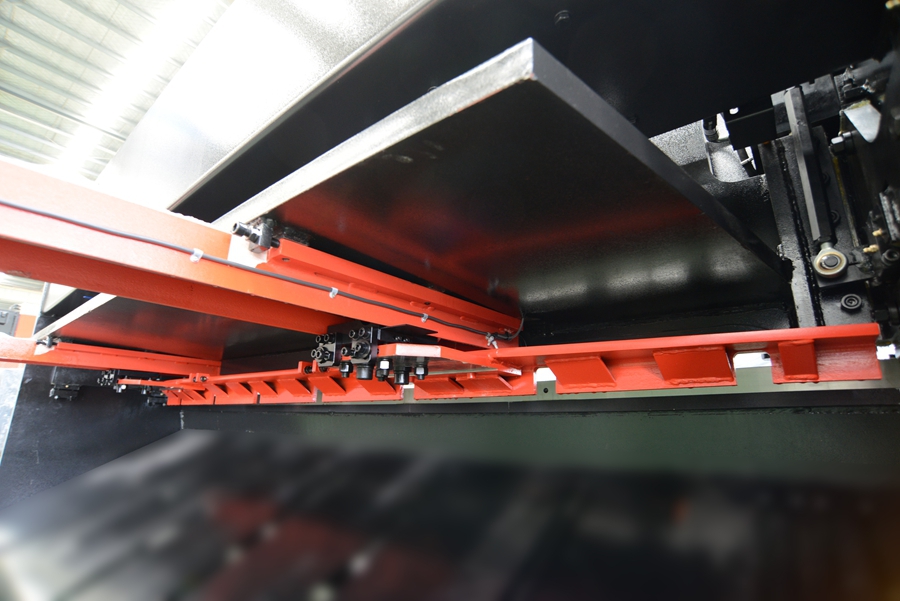

7. Four-side shearing blade is adopted to improve the service life of blade which is much better than that of swing shear.

8、New design of backgauge,stable structure,improve Wear resistance, the crashworthiness a lot

2. Adopts Delem DAC360 CNC system:

● precisely control backgauge

●precisely control shearing stroke

● precisely control shearing angle

●precisely control blades clearance

●precisely control number of jobs.

3. Adopts Germany BOSCH integrated hydraulic system:

● to simplify the pipeline

●to avoid oil leakage

● to improve the working stability

● to beautify the machine appearance

1. used for the auto control of shearing machine with full-functional front-feeding or backgauge

2. adopts high definition LCD display, menu type programming;

3. shearing angle, blade gap, shearing stroke auto calculation and control;

4. modular construction, flexible definition or extend X1-X2 synchronized feeding control and auxiliary Z axis control;

5. adopts absolute position and relative position programming;

6. auto search of reference point, and the memory off-position can be set;

7. unique hand wheel design to make machine adjustment conveniently;

8. RS232 serial interface;

9. output of multi user-defined auxiliary signals;

10. self diagnosis program;

11. internal storage of 100 program line;

12. 4.7 inch high definition LCD;

13. function of program counting;

14. size unit selection between metric system and English system.

| No. | Item | Qty. | Remark |

| 1 | Machine Files | One set | |

| 2 | Hex Socket Spanner | One set | |

| 3 | Grease Gun | One no. | |

| 4 | Grounding Bolt | One set | |

| 5 | Adjusting Bolt | One set | |

| 6 | Foot Control | One no. |

1. Air source: make sure the gas pressure supplied to the machine should be more than 0.6 Mpa, the gas flow should be more than 0.3 m3/min.

2. Hydraulic oil: imported VG46# anti-wear hydraulic oil. The required oil mass is set below:

| Machine Model | Oil Mass (L) |

| VR6,VR8 series | 230 |

| VRZ series | 690 |

| VR10 series | 370 |

| VR13*3200 | 460 |

| VR13*6200 | 800 |

3.Power: 380V,50HZ, voltage fluctuation ±10%

4. Environment temperature: 0°C - +40°C

5. Environment humidity: relative humidity 20-80%RH(non-condensing)

6. Keep away from the strong vibration source and electromagnetic interference

7. Little dust, no harmful or corrosive gas

8. Prepare the foundation according to the foundation drawing

9. Select the relative personnel with certain education background for a long-term arrangement as machine operator.

CNC Shearing Machine;hydraulic guillotine shear;shearing machine;cnc shearing

2500

| Description | Unit | 6*2500 | |

| Shearing Thickness (mm) |

Mild Steel 450Mpa | mm | 0.5-6 |

| Stainless Steel 600Mpa | 0.5-4 | ||

| Aluminum 300Mpa | 0.5-8 | ||

| Shearing Length | mm | 2500 | |

| Shearing Angle | ° | 0.5°~2° | |

| Back- gauge |

Stroke mm | mm | 5~1000 |

| Speed mm/s | mm/s | ≤250 | |

| Accuracy mm | mm | ±0.1 | |

| Servo Motor Power KW | KW | 1 | |

| Stroke Times | hpm | 25-36 | |

| Cylinder Capacity (L) | L | 230 | |

| No. of Clamping | no. | 12 | |

| Main Motor Power (KW) | KW | 11 | |

| CNC System | Holland Delem DAC360 CNC system controlling shearing angle, blades gap, and shearing stroke | ||

| No. and length of support arm (mm) | mm | 3*1400 | |

| Outline Dimension | Length (mm) | mm | 3110 |

| Width (mm) | mm | 3000 | |

| Height (mm) | mm | 1705 | |

3000/3200

| Description | Unit | 6*3000 | 8*3000 | 10*3000 | 13*3200 | 16*3200 | ||||

| Shearing Thickness (mm) |

Mild Steel 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||

| Stainless Steel 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||

| Aluminum 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||

| Shearing Length | mm | 3070 | 3070 | 3070 | 3200 | 3200 | ||||

| Shearing Angle | ° | 0.5°-2° | 0.5°-2° | 0.5°-2° | 0.5°-2° | 0.5°-2° | ||||

| Back- gauge |

Stroke mm | mm | 5~1000 | 5~1000 | 5~1000 | 5-1000 | 5-1000 | |||

| Speed mm/s | mm/s | ≤250 | ≤250 | ≤250 | 200 | 200 | ||||

| Accuracy mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||

| Servo Motor Power KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||

| Stroke Times | hpm | 22-35 | 16-34 | 15-32 | 10-15 | 9-16 | ||||

| Cylinder Capacity (L) | L | 230 | 230 | 370 | 460 | 460 | ||||

| No. of Clamping | no. | 14 | 14 | 14 | 15 | 15 | ||||

| Main Motor Power (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||

| CNC System | Holland Delem DAC360 CNC system controlling shearing angle, blades gap, and shearing stroke | |||||||||

| No. and length of support arm (mm) | mm | 3*1400 | 3*1400 | 3*1400 | 3*1000 | 3*1000 | ||||

| Outline Dimension | Length (mm) | mm | 3610 | 3640 | 3720 | 4075 | 4300 | |||

| Width (mm) | mm | 3000 | 3000 | 3040 | 2752 | 3000 | ||||

| Height (mm) | mm | 1705 | 1755 | 1880 | 2432 | 2850 | ||||

4000

| Description | Unit | 6*4000 | 8*4000 | 10*4000 | 13*4000 | 16*4000 | ||||||

| Shearing Thickness (mm) |

Mild Steel 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||||

| Stainless Steel 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||||

| Aluminum 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||||

| Shearing Length | mm | 4070 | 4070 | 4070 | 4000 | 4000 | ||||||

| Shearing Angle | ° | 0.5°~2° | 0.5°~2° | 0.5°~2° | 0.5°~2.5° | 0.5°~2.5° | ||||||

| Back- gauge |

Stroke mm | mm | 5~1000 | 5~1000 | 5~1000 | 5-1000 | 5-1000 | |||||

| Speed mm/s | mm/s | ≤250 | ≤250 | ≤250 | ≤200 | ≤200 | ||||||

| Accuracy mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||||

| Servo Motor Power KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||||

| Stroke Times | hpm | 16~34 | 14~32 | 12~32 | 10-15 | 8-15 | ||||||

| Cylinder Capacity (L) | L | 230 | 230 | 370 | 460 | 460 | ||||||

| No. of Clamping | no. | 18 | 18 | 18 | 19 | 19 | ||||||

| Main Motor Power (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||||

| CNC System | Holland Delem DAC360 CNC system controlling shearing angle, blades gap, and shearing stroke | |||||||||||

| No. and length of support arm (mm) | mm | 4*1400 | 4*1400 | 4*1400 | 4*1000 | 4*1000 | ||||||

| Outline Dimension | Length (mm) | mm | 4610 | 4640 | 4720 | 4970 | 5300 | |||||

| Width (mm) | mm | 3000 | 3000 | 3040 | 2760 | 3000 | ||||||

| Height (mm) | mm | 1705 | 1705 | 1880 | 2562 | 2850 | ||||||

6000/6200

| Description | Unit | 6*6000 | 8*6000 | 13*6200 | 16*6000 | 16*6200 | |||

| Shearing Thickness (mm) |

Mild Steel 450Mpa | mm | 0.5~6 | 0.8~8 | 1-13 | 1-16 | 1-16 | ||

| Stainless Steel 600Mpa | 0.5~4 | 0.8~5 | 1-8 | 1-10 | 1-10 | ||||

| Aluminum 300Mpa | 0.5~8 | 0.8~10 | 1-18 | 1-20 | 1-20 | ||||

| Shearing Length | mm | 6140 | 6140 | 6200 | 6000 | 6200 | |||

| Shearing Angle | ° | 0.5˚-2˚ | 0.5˚-2.5˚ | 0.5˚-2.5˚ | 0.5˚-2.5˚ | 0.5˚-2˚ | |||

| Back- gauge |

Stroke mm | mm | 5-1000 | 5-1000 | 5-1000 | 5-1000 | 5-1000 | ||

| Speed mm/s | mm/s | 200 | 200 | 200 | 200 | 200 | |||

| Accuracy mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |||

| Servo Motor Power KW | KW | 1.0 | 1.0 | 1.0 | 1.5 | 2.0 | |||

| Stroke Times | hpm | 12~20 | 12~20 | 6-10 | 5-9 | 5-9 | |||

| Cylinder Capacity (L) | L | 690 | 690 | 800 | 800 | 800 | |||

| No. of Clamping | no. | 29 | 29 | 27 | 27 | 27 | |||

| Main Motor Power (KW) | KW | 11 | 15 | 30 | 37 | 37 | |||

| CNC System | Holland Delem DAC360 CNC system controlling shearing angle, blades gap, and shearing stroke | ||||||||

| No. and length of support arm (mm) | mm | 6*1000 | 6*1000 | 6*1000 | 6*1000 | 6*1000 | |||

| Outline Dimension | Length (mm) | mm | 7055 | 7115 | 7220 | 7300 | 7500 | ||

| Width (mm) | mm | 2686 | 2690 | 2945 | 3000 | 3000 | |||

| Height (mm) | mm | 2495 | 2680 | 2850 | 2850 | 2850 | |||

V R(Z)Series:

| No. | Name | Model | Brand |

| 1 | CNC System | DAC360 CNC System | Holland Delem |

| 2 | Servo Motor | EMJ-10APB22 | Estun |

| 3 | Servo Driver | RONET-E-10A-AMA | Estun |

| 4 | Hydraulic System | Electro-servo hydraulic valve set | Germany Bosch-Rexroth |

| a.proportional pressure valve | |||

| b.cartridge valve | |||

| c.electromagnetic selector valve | |||

| d.overlay pressure valve | |||

| e.hydraulic control one-way valve | |||

| f.throttle valve | |||

| e.one-way valve etc. | |||

| 5 | Linear guideway | HSR25A-1240L | THK or PMI |

| 6 | Ballscrew | 25/20-1400mm | THK or PMI |

| 7 | Oil pump | IPH-5B-50-11or PGH4-3X/050-E11VU2 | Japan NACHI pump or Germany Rexroth |

| 8 | Complete set of sealing ring in oil cylinder | USA PARKER | USA PARKER |

| 9 | Complete set of high pressure pipeline | 1.F372C91C161608-1200mm | USA PARKER、EO-2 pipe joint or Germany VOSS pipe joint |

| 2.F372C91C161608-1950mm (2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4.F381CFCF151508-2140mm (3140mm) | |||

| 5.F451TCCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Or F3720C1C202512-1300mm |

|||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF etc. | |||

| 10 | Coupling | R38 25.385/42 etc. | Germany KTR |

| 11 | AC contactor | LC1-D38B7C、LC1-D25B7Cetc. | Schneider |

| 12 | Proximity switch | TP-SM5P2 etc. | TEND |

| 13 | Terminal lead | TB2.5B TB16ICH etc. | Phoenix |

| 14 | Button | XB2-BVB3LC etc. | Schneider |

| 15 | Painting | KAILEDI |

V R(Z)Series:

| No. | Name | Model | Brand |

| 1 | CNC System | DAC360 CNC System | Holland Delem |

| 2 | Servo Motor | EMJ-10APB22 | Estun |

| 3 | Servo Driver | RONET-E-10A-AMA | Estun |

| 4 | Hydraulic System | Electro-servo hydraulic valve set | Germany Bosch-Rexroth |

| a.proportional pressure valve | |||

| b.cartridge valve | |||

| c.electromagnetic selector valve | |||

| d.overlay pressure valve | |||

| e.hydraulic control one-way valve | |||

| f.throttle valve | |||

| e.one-way valve etc. | |||

| 5 | Linear guideway | HSR25A-1240L | THK or PMI |

| 6 | Ballscrew | 25/20-1400mm | THK or PMI |

| 7 | Oil pump | IPH-5B-50-11or PGH4-3X/050-E11VU2 | Japan NACHI pump or Germany Rexroth |

| 8 | Complete set of sealing ring in oil cylinder | USA PARKER | USA PARKER |

| 9 | Complete set of high pressure pipeline | 1.F372C91C161608-1200mm | USA PARKER、EO-2 pipe joint or Germany VOSS pipe joint |

| 2.F372C91C161608-1950mm (2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4.F381CFCF151508-2140mm (3140mm) | |||

| 5.F451TCCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Or F3720C1C202512-1300mm |

|||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF etc. | |||

| 10 | Coupling | R38 25.385/42 etc. | Germany KTR |

| 11 | AC contactor | LC1-D38B7C、LC1-D25B7Cetc. | Schneider |

| 12 | Proximity switch | TP-SM5P2 etc. | TEND |

| 13 | Terminal lead | TB2.5B TB16ICH etc. | Phoenix |

| 14 | Button | XB2-BVB3LC etc. | Schneider |

| 15 | Painting | KAILEDI |