Our Factory

We have 37,483 m² modern intelligent manufacturing facility and 21,000 m² workshop, featuring a crucial 4,000 m² constant temperature workshop. This provides an ultra-stable environment for producing high-precision components, ensuring ultimate product performance from the source. Our independent 400 m² inspection center performs rigorous reliability verification on every production line. The factory's "brain"—our 400 m² intelligent manufacturing control center—deeply integrates Industry 4.0 and IoT to monitor and optimize processes, ensuring that we deliver a complete, efficient, reliable, and data-driven manufacturing solution.

Factory Overview

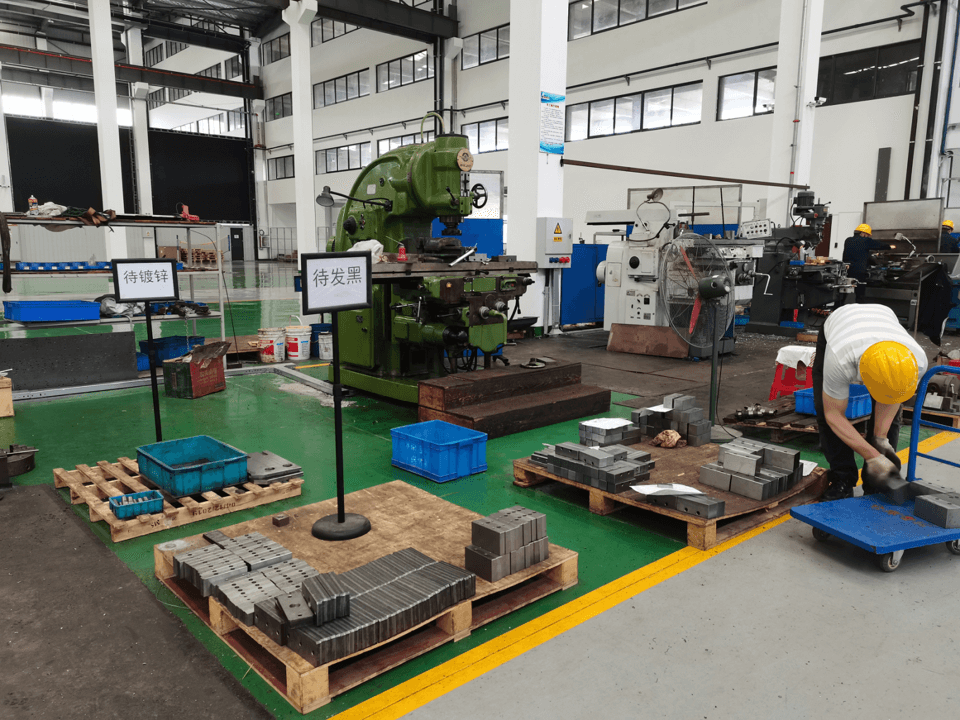

Machining & Repair Workshop

Our in-house Machining & Repair workshop manufactures critical components, giving us full control over quality, customization, and rapid prototyping. This provides robust technical backup, ensuring a swift response for customer repairs and spare parts to guarantee your line's long-term stability.

Electrical Room

Our Electrical Room is key to ensure maximum uptime. We manage proactive maintenance, rapid fault response, and expert installation for all systems. This commitment to electrical reliability and safety is reflected in every production line we deliver.

Assembly Workshop

In the Assembly Workshop, we execute the final, most critical stage: transforming precision components into excellent complete machines. Following lean principles, we precisely complete every assembly step on our efficient lines. Strict in-all process and final testing are our unwavering commitment to quality.

Warehouse

Our warehouse plays a vital role in the manufacturing supply chain.we use our WMS and automated equipment to intelligently manage a vast inventory of components. We strictly adhere to FIFO and JIT principles, providing timely and accurate material supply to our assembly lines.